Missouri Agribusiness and Farmers MOhemp Energy wants to work with you and is actively seeking: Partners, Investors, Advisers, Team Members, Farmers: who are interested in: Biomass, Biofuels, Hemp Lignin, Energy Conserving Building Products, Hemp Oil, Hemp Fibers, Medical Cannabis, Phytoremediation,

Search This Blog

Showing posts with label hemp fiber. Show all posts

Showing posts with label hemp fiber. Show all posts

Thursday, April 25, 2019

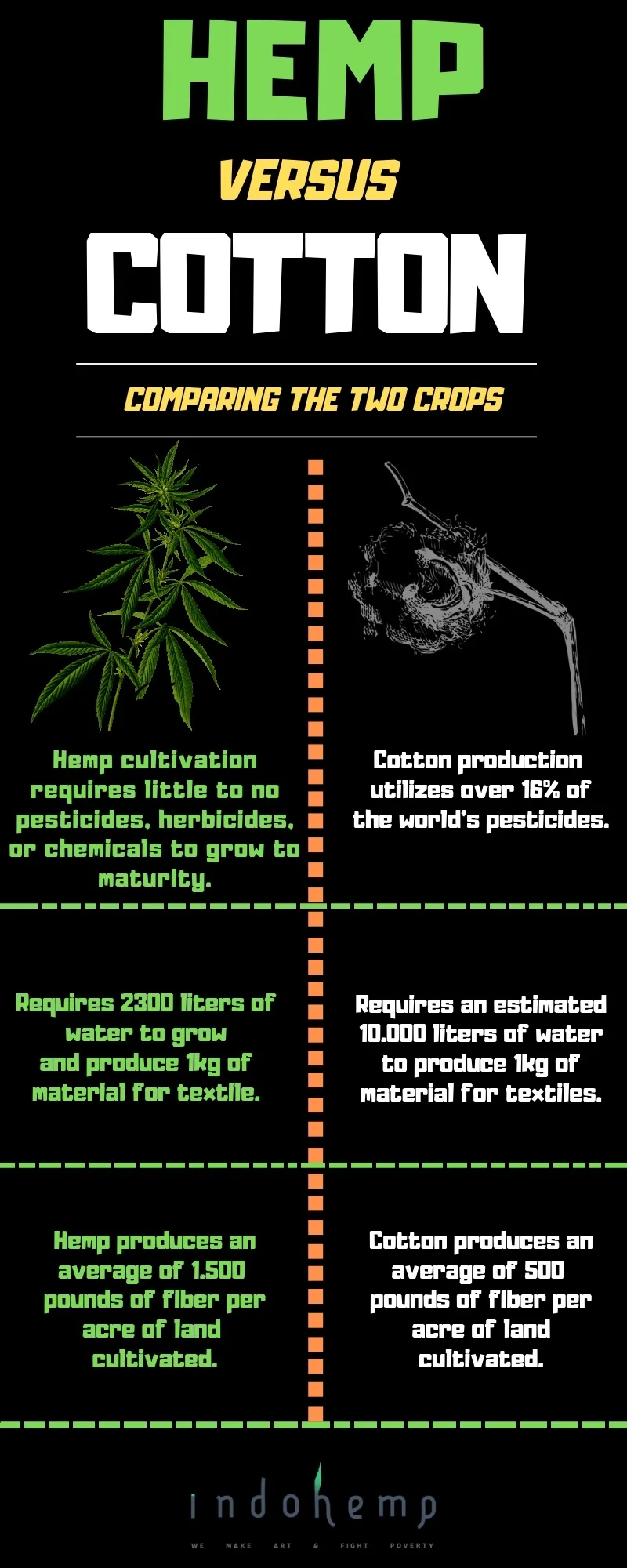

Indohemp - Hemp vs Cotton

Labels:

cotton,

hemp fiber,

hemp vs cotton

I believe the power is in our hands to build a world that will benefit everyone.

Tuesday, May 10, 2016

Hemp: A Source Biomass Antibacterial Fibers

Cannabis sativa: The Plant of the Thousand and One Molecules

Plant lignocellulosic biomass is an abundant renewable resource, which can provide biopolymers, fibers, chemicals and energy (Guerriero et al., 2014, 2015, 2016).

Trees are important for the provision of wood, however, also fast-growing herbaceous species, like textile hemp (which has a THC content <0.3%; Weiblen et al., 2015), can provide high biomass quantities in a short time. The stem of this fiber crop supplies both cellulosic and woody fibers: the core is indeed lignified, while the cortex harbors long cellulose-rich fibers, known as bast fibers (Figure 1) (Guerriero et al., 2013).

FIGURE 1

FIGURE 1. Anatomical details of Cannabis stem. (A) Stem of an adult plant (ca 2 months); (B) The stem can be peeled off and shows a lignified core and a cortex with bast fibers. (C) Longitudinal section of hemp stem stained with toluidine blue

showing the cortex with a bundle of bast-fibers (white asterisk) and the core with xylem vessels (black asterisk).

This heterogeneous cell wall composition makes hemp stem an interesting model to study secondary cell wall biosynthesis, in particular the molecular events underlying the deposition of cortical gelatinous bast fibers and core woody fibers.

Cannabis woody fibers (a.k.a “hurds” or “shivs”) are used for animal bedding because of their high absorption capacity and for the creation of a concrete-like material.

Hemp bast fibers are used in the biocomposite sector as a substitute of glass fibers. The automotive industry is particularly keen on using hemp bast fibers to produce bioplastics: this material is stronger than polypropylene plastic and lighter in weight (Marsh, 2003).

Beyond the applications in the construction and automotive industries, hemp fibers are attractive also in the light of their natural antibacterial property. Hemp bast fibers have been indeed described as antibacterial (Hao et al., 2014; Khan et al., 2015) and their use for the manufacture of an antibacterial finishing agent (Bao et al., 2014), surgical devices (Gu, 2006) or functionalized textiles (Cassano et al., 2013) has been reported. This property is linked to the chemical composition of hemp bast fibers: both free and esterified sterols and triterpenes have been identified, among which β-sitosterol and β-amyrin (Gutiérrez and del Río, 2005). These compounds possess known antibacterial properties (Kiprono et al., 2000; Ibrahim, 2012). Hemp bast fibers were also found to contain cannabinoids (2% of the total metabolite extract) (Bouloc et al., 2013 and references therein). More recently hemp hurd powder showed antibacterial properties against Escherichia coli (Khan et al., 2015). Since the hurd has a higher lignin content than the bast fibers, its antibacterial property may be linked to lignin-related compounds such phenolic compounds, as well as alkaloids and cannabinoids (Appendino et al., 2008; Khan et al., 2015).

Hemp Stem: A Source of Fibers with Antibacterial Properties

REVIEW ARTICLE

Front. Plant Sci., 04 February 2016 |http://dx.doi.org/10.3389/fpls.2016.00019

Christelle M. Andre*,

Christelle M. Andre*,  Jean-Francois Hausman and

Jean-Francois Hausman and  Gea Guerriero

Gea Guerriero

- Environmental Research and Innovation, Luxembourg Institute of Science and Technology, Esch-sur-Alzette, Luxembourg

Labels:

Ag Investors,

Agriculture,

Hemp,

Hemp Bast,

Hemp Biomass,

hemp fiber,

Hemp Hurd,

Hemp Lignin,

Hemp Stalk,

Hemp Stem,

Lignin

I believe the power is in our hands to build a world that will benefit everyone.

Friday, December 4, 2015

Kenaf Fibers For Sale 300T

My Hemp and Kenaf Farm contact has just informed me that they have 300 Tons of recently harvested and baled Kenaf Fibers for sale.

Below are images of the Kenaf Fiber Bales. If I can assist you in anyway let me know. Feel free to use the contact form or send me an email.

Labels:

Hemp Farming,

hemp fiber,

Hemp Seed,

kenaf,

Kenaf Fibers For Sale,

Kenaf Seeds

I believe the power is in our hands to build a world that will benefit everyone.

Wednesday, November 18, 2015

Hemp and Kenaf Farm Images

Hemp and Kenaf Farm images from my latest Hemp Farm Connection that sells:

- Hemp Seeds for Fiber or Seed,

- Kenaf Seeds,

- Hemp Hurds in 3 different sizes for different applications and uses,

- Hemp Fibers

- Kenaf Fibers

- Mobile and Stationary Equipment needed to process your Hemp or Flax into sellable and useable items.

And the best part is that this is a Family Operation!

Labels:

Hemp Farming,

hemp fiber,

Hemp Seed,

Kenaf Seeds

I believe the power is in our hands to build a world that will benefit everyone.

Industrial Hemp is Four Crops

$580 Million US Market in 2014 22% Market Growth

Seed

Bast Fiber

Core Fiber

Industrial Hemp is Four Crops

Greens

24% 240,000 PPM

Mari- juana

Hemp vs Marijuana

It’s been said that all crows are blackbirds,...

but not all blackbirds are crows.

Marijuana is a man-made cultivar of hemp specifically bred to be high in THC.

Industrial Hemp has been bred for centuries to be low in THC - so low it is virtually not there.

Standard for THC in Industrial Hemp

The same can be said for industrial hemp and its hallucinogenic cousin marijuana.

0.30% Marijuana 3,000 PPM

is hemp, but Industrial Hemp is not Marijuana.

0.005%

0.001% 50 PPM

10 PPM

THC in commercial hemp oil

for Canadian Standard

hemp oil

Vote Hemp.

A modified harvester can remove seed and stalk at the same time.

Hemp has been called the plant of 25,000 uses - as long as you don’t use it in the United States. Many of its traditional markets have shrunk or gone overseas since it was banned in 1937. It is unlikely they will come back.

But a new generation has discovered the powerful nutritional benefits and the new markets for biocomposites that make a strong case for hemp’s valuable contributions to our health, environment and economy.

The Hemp Seed is rich in Omega-3 oil and amino acids. In all the plant kingdom, nothing so matches the brain’s Omega oil profile as hemp seed.

Packaged Nut Hemp Milk Hemp Butter

Hemp Nut

Hemp is Highly Nutritious Food

Cracking

Shell

Oil

Food Fiber

Food Personal

Care

Industrial

Soap Shampoo Lotion Salad Oil EFA Supplement

Paints Lubricants Margarine

Bio Diesel

Pressing

Seed Cake

Animal Feed Protein Powder

Scutching Hackling Carding Combing Sizing

Hemp is Two Fibers

Different Retting Methods

Ground Enzyme

Water Steam Different retting processes may be used to separate fiber from stalk

Retted stalks are baled and shipped for

Long

Decorticator

Decorticating

Plant Fibre

Fiber Waste (20%)

Core

Geotextiles

Fuel Pellets Insulation Cordage Textiles Paper Fiber Reinforced Plastics

Animal Bedding HempCrete Particle Board Wood Flour

The Long and Short of it

Pressboard, Fiberboard and Chipboard

Short Fibre

Breaking Sizing Cleaning Packaging

Which Fiber Should be Banned?

Of the 46 pesticides used, 20 are moderately hazardous, 8 are highly hazardous and 5 are extremely hazardous

Hemp requires little input, but it loves nitrogen. It works well

Worldwide Everything

Cotton Else Combined Pesticide Market Share per Acre

in rotation with vegetables using their leftovers.

Hemp likes a good rain now and then. It can protect waterways by absorbing nutrients with strong roots to hold farm runoff.

Hemp is good for soil. Its roots go deep to find water and aerate the soil. Farmers leave the stubble as a soil conditioner.

Farmers leave the stalks on the ground to dry and ret. The leaves fall off returning nitrogen and adding tilth.

Hemp grows so tall and dense it drives out weeds. Farmers employ it in rotation to remove weeds naturally for organic crops to follow.

24% of the world’s pesticides are applied to cotton, and only a quarter of that lands on target. Worse, it’s not much land.

Cotton is the world’s thirstiest crop depleting ground water and polluting river basins.

Cotton depletes the soil and heavy irrigation poisons the land with salts.

Cotton uses defoliants before harvest.

Cotton requires chemical weed control.

Hemp is called Evil. Cotton is called Natural.

Hemp vs Cotton

Cars must eliminate their landfill requirement, increase their recyclability, reduce their weight and reduce their carbon footprint.

Hemp fiber added to bio-plastic resins does all that.

Lotus made the whole car of hemp composites.

The Mercedes C-class uses 20 kilograms of hemp to make reinforced plastic panels for doors, headliners, trunk liners, glove boxes and consoles.

Bio-Resin

Fillers Additives

Wood Flour Ground Glass Glass Bubbles

Mixer

A wide range of products are possible for Sheet Molding Compound.

Pultrusion Molding

Cord Belt or Sheet

UV or Heat Curing

Produces Rods, Strips, Sheets or Custom Profiles (eg. Decking)

Sheet Molding and Pultrusion are two plastic molding methods that are readily converted to Bio-Resins and natural fibers. At End of Life, the parts can be chipped and molded into large objects such as highway furniture.

BioResin

To

Warehouse

Bio-Composites Stronger & Lighter

Takeup Reel

Top Film

Chopper

Bottom Film

Sheet Molding Compound Machine

Hemp Fiber Roving

Hempcrete is a biocomposite

formed with Lime and Hemp Shiv. It is renewable, recyclable and sustainable. It makes quiet, energy efficient housing (R30-R50 insulation) with no synthetic materials and an excellent 2-hour fire rating.

The walls breathe inhibiting the formation of mold and mildew causing no asthma or allergies. No “sick building syndrome” forcing premature demolition.

$65,000 of hemp shiv, lime binder and lime render were imported from England - money that could go to American farmers and producers. Approximately 4 acres of hemp were used.

Water, Lime and Shiv are lightly mixed in a conventional mortar mixer. The mixture is lightweight and easily skidded around the site.

When dry, a special lime-based hard render exterior is applied similar to stucco.

The brick face was specially designed to maintain breathability.

Annual energy savings is about $900 per year.

When dry, hempcrete is about a seventh of the weight of cement. It floats in water. Material is poured between forms and tamped down. It sets up sufficiently to pull forms in as little as an hour. The material is light and can be passed bucket-brigade fashion to workers on scaffolding.

With forms removed, the walls are protected from rain for a week and kept moist to control the curing.

Hempcrete can be applied as loose-fill insulation. The attic is filled 12” of loose fill. The mixture uses less binder, but the lime continues to provide the fire rating.

The curtains are removed and the walls are left to dry and cure.

Tarpon Springs, FL

The house absorbed about 14 tons of CO2. Hempcrete can last a thousand years sequestering carbon all the while.

Hemp Makes Healthy Efficient Houses

Hemp for Phytoremediation

Hemp roots go deep to pull contaminants up into the canopy.

Hemp absorbs heavy metals like Lead, Cadmium and even radioactive Cesium.

The metals concentrate in the leaves. Stalks and seed are little affected.

Dried leaves can be crushed to reduce volume and trucked away for disposal.

Stalks can be processed in the conventional manner for fiber. Seed might be safe for animal feed.

Hemp is being used to remediate Radioactive Cesium at Chernobyl. Fukushima is also studying it.

America’s Hanford, WA site is not allowed to use Hemp.

Containment Booms

Florida has experienced oil spills on our beaches just from shipping accidents in our ports. Many Floridians filed claims in the aftermath of the Deepwater Horizon Spill.

Hemp is very absorbent. The hemp core can be blown into simple netting material to make containment booms from all natural fiber for about a quarter of the price of synthetic booms.

Florida can produce enough hemp to make a hundred thousand miles of 12” boom - enough to surround many Deepwater Horizon spills. It can be stored and shipped on large reels and cut to size for the immediate need. It is lightweight and can be flown to disasters.

There is no reason barges of inexpensive boom material can’t be stored in all our ports ready for immediate deployment.

The used material can be incinerated or composted depending on the material contained. But Paul Stamets, a noted mycobiologist, has shown that the best way to remove oil is to plant wood eating fungii. Oyster mushrooms work the best, and hemp core is woody material. Paul uses hemp rope inoculated with oyster mushroom spores as the starter medium for his mushroom farm.

It’s possible you could eat the next oil spill. Or maybe you’d rather eat the last one...

Labels:

Hemp Farming,

hemp fiber,

Hemp Food,

Hemp For Victory 2016

I believe the power is in our hands to build a world that will benefit everyone.

Sunday, November 15, 2015

Bulk Hemp or Flax Machines and Products Available

|

| Hemp Rope Bulk Rolls |

|

| Natural Hemp Fiber |

|

| Bulk Shipping of Hemp and Kenaf |

|

| Hemp and Kenaf Samples |

|

| Hemp Hurd Bulk Packages |

World Wide Shipping Options

| Kenaf Fibers |

Use the contact form for additional detail.

Labels:

Hemp,

hemp fiber,

Industrial Hemp Products and Markets,

kenaf,

MOhemp Mobile Hemp Processing Equipment,

MOhemp Seeds

I believe the power is in our hands to build a world that will benefit everyone.

Tuesday, August 11, 2015

The Future Value in the Lignin Market

Lignin Market is Expected to Reach US$ 985.5 Mn in 2023

Posted On Jun 22, 2015

Transparency Market Research has published a new report titled

“Lignin Market - Global Industry Analysis, Size, Share, Growth, Trends and Forecast, 2015 - 2023.”

According to the report, the global lignin market was valued at US$ 782.3 Mn in 2014 and is anticipated to

reach US$ 985.5 Mn by 2023, expanding at a CAGR of 2.7% from 2015 to 2023. The global lignin

market demand by volume stood at 1115.4 Kilo Tons in 2014.Increase in niche application of lignin

in various fields such as building and construction, agrochemicals, and paints and coatings is contributing

to the growth of the global lignin market. Functional properties offered by lignin is the major factor leading

to high demand for lignin in the market. Usage of lignin as a dispersant, binder, and emulsifying agent

has attracted the attention of major manufacturers in various end-user industries. Additionally, industrial

expansion in developing economies such as Asia Pacific is propelling demand for lignin across the

globe. These factors are likely to drive demand for lignin for applications such as concrete additive,

animal feed, and dye stuff.

“Lignin Market - Global Industry Analysis, Size, Share, Growth, Trends and Forecast, 2015 - 2023.”

According to the report, the global lignin market was valued at US$ 782.3 Mn in 2014 and is anticipated to

reach US$ 985.5 Mn by 2023, expanding at a CAGR of 2.7% from 2015 to 2023. The global lignin

market demand by volume stood at 1115.4 Kilo Tons in 2014.Increase in niche application of lignin

in various fields such as building and construction, agrochemicals, and paints and coatings is contributing

to the growth of the global lignin market. Functional properties offered by lignin is the major factor leading

to high demand for lignin in the market. Usage of lignin as a dispersant, binder, and emulsifying agent

has attracted the attention of major manufacturers in various end-user industries. Additionally, industrial

expansion in developing economies such as Asia Pacific is propelling demand for lignin across the

globe. These factors are likely to drive demand for lignin for applications such as concrete additive,

animal feed, and dye stuff.

|

| Lignin Removal last step in MOhemp Energy Mobile Processing System |

Lignosulfonates account for major share of the global lignin market.

Demand for these sulfur-free lignins is high in the construction industry

due to its high absorbency rate and zeta potential to cement particles.

Lignosulfonates are used on a large scale in the production of cement,

as these reduce the viscosity of slurry by decreasing the amount of water

used in the production of cement. Lignin provides high-performance

concrete strength; thus, it reduces the damage caused by moisture

and acid rain. Hence, high demand for lignin in the building & construction

industry is estimated to boost demand for lignosulfonates globally.

Lignin produced though the kraft pulping process is known as kraft lignin.

This lignin dominates the sulfite pulping process. Kraft lignin

possesses different chemical properties than lignosulfonates. Therefore,

it is used in the manufacture of dyes and insecticides. Kraft lignin

accounted for more than 5% share of the global lignin market in 2014.

The segment is projected to gain market share during the forecast period.

The others segment (including organosolv) is also likely to drive demand

for lignin at a steady rate in the near future.

Read full Article here: http://www.transparencymarketresearch.com/pressrelease/lignin-market.htm

Not Listed on the following chart is how: "Hemp Lignin is being used in Electronics."

Most people don’t understand the truly diverse value of hemp (Cannabis sativa). Cultures have depended on this hardy plant for centuries for clothing, fabric, and paper. Today, it is also used for food, fuel, medicine, building materials, and plastics. Now the energy storage industry is starting to take notice, thanks to new Canadian research that shows supercapacitors with electrodes made from hemp-based carbon nanosheets outperform standard supercapacitors by nearly 200%.

After discussing the Invention process with another StLouis ...

2 days ago - Scottys Mobile Hemp Processing Equipment and Process of removing the Lignin from the fibers will be Patent Protected. Better safe than sorry when a prior Hemp ...

Graphene, a carbon nanomaterial, is considered to be one of the best materials for supercapicitor electrodes. Graphene is, however, expensive to manufacture, costing as much as $2,000 per gram. Looking for a less-costly solution, researchers at the University of Alberta/National Institute for Nanotechnology (NINT) NRC, and Alberta Innovates-Technology Futures, led by chemical and materials engineering Professor David Mitlin, developed a process for converting fibrous hemp waste into a unique graphene-like nanomaterial that outperforms graphene. What’s more, it can be manufactured for less than $500 per ton... article link

I believe the power is in our hands to build a world that will benefit everyone.

Subscribe to:

Posts (Atom)