MOhemp is preparing for another Kenaf growing experiment. This experiment will replicate no-till farming with cover crops.

Its winter time in Missouri and cold outside so this Kenaf growing experiment will be performed inside a acclimatized location of the office with pots and plant trays. Today, I brought the dirt and kenaf stems/leaves (that will be used to replicate cover crop farming) in from outside and will be letting it acclimate to room temperature (70 Deg F) before adding seeds.

The kenaf plants used for the Cover Crop were produced in the prior experiment 2016 this year. (Kenaf Plant Timeline Pictures)

(A portion of the seeds used in this growing experiment will be from the plants grown earlier this year.)

If as predicted, the seeds sprout and grow I will have verified my earlier claim that Kenaf will produce seeds that will grow in Midwest USA.

Kenaf sprouts in 2-4 days so I will have information on the sprouts pretty quick. If they grow like the other plants have done. I predict the sprouts to have grow out of the cover crop mulch system in less than a week. At that time they will be receiving full sunlight and will grow into the 12 foot giants in a matter of months.

As a reminder for anyone reading this post. I am growing Kenaf because Hemp is illegal to grow in my state. Kenaf is also known as Indian Hemp in a few circles.

In the orient I see pictures of Kenaf growing 18 feet tall. Kenaf is a biomass energy champion that needs less water to grow than hemp as well.

Its winter time in Missouri and cold outside so this Kenaf growing experiment will be performed inside a acclimatized location of the office with pots and plant trays. Today, I brought the dirt and kenaf stems/leaves (that will be used to replicate cover crop farming) in from outside and will be letting it acclimate to room temperature (70 Deg F) before adding seeds.

The kenaf plants used for the Cover Crop were produced in the prior experiment 2016 this year. (Kenaf Plant Timeline Pictures)

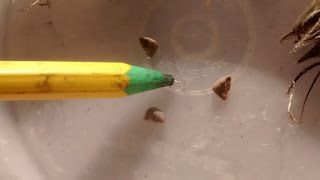

(A portion of the seeds used in this growing experiment will be from the plants grown earlier this year.)

|

| Kenaf Seeds from plants grown in Missouri |

If as predicted, the seeds sprout and grow I will have verified my earlier claim that Kenaf will produce seeds that will grow in Midwest USA.

Kenaf sprouts in 2-4 days so I will have information on the sprouts pretty quick. If they grow like the other plants have done. I predict the sprouts to have grow out of the cover crop mulch system in less than a week. At that time they will be receiving full sunlight and will grow into the 12 foot giants in a matter of months.

As a reminder for anyone reading this post. I am growing Kenaf because Hemp is illegal to grow in my state. Kenaf is also known as Indian Hemp in a few circles.

In the orient I see pictures of Kenaf growing 18 feet tall. Kenaf is a biomass energy champion that needs less water to grow than hemp as well.