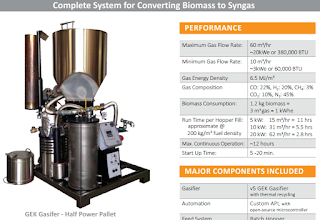

Technical parameters of biomass (straw) fluidized bed gasifier system

1. Straw storage, 2. Delivery 3. Silos 4. Fluidized bed gasifier, 5. Cyclone 6. Pipe dust collector

7. Electric catcher 3. Spray tower 9. Circulating liquid separator 10. Fan 11. Buffer tank 12. Water seal tank 13. Generator set

Technical parameters of biomass (straw) fixed bed gasifier system

1. Straw storage, 2. Delivery 3. Fixed bed gasifier 4. Cyclone 5. Air cooler 6. Intercooler

7. Electric catcher 3. Intercooler 13. Fan 9. Separator 10. Buffer tank 11. Water seal 12. Generator set

After crushing the straw is applied with a biomass straw using a fluidized bed gasifier. Advantages: cost savings, shortcomings: do not use storage.

The briquettes are applied after the briquettes are used with the biomass straw fixed bed gasifier. Advantages: high efficiency, conducive to transport and storage, shortcomings: increase costs.

1, the caloric value of straw biomass resources

The caloric value of the straw was 3687 Kcal / kg (7.8% moisture, 69.11% volatiles, 5.71% ash, 17.38% fixed carbon)

The caloric value of cotton stalk 3591Kcal / kg (13.4% moisture, 65.17% volatile, ash 3.20%, fixed carbon 18.23%)

The caloric value of corn stalks was 3813 Kcal / kg (9.5% moisture, 70.31% volatiles, 4.01% ash, 16.18% fixed carbon)

The caloric value of straw is 3139 Kcal / kg (11.6% moisture, 59.5% volatile, 14.1% ash, 14.8% fixed carbon)

3, the characteristics of straw biomass resources

Widely distributed, small density, light weight.

Can be compressed into particles or biomass blocks for easy transport and storage.

High fuel volatile, easy to fire, good combustion characteristics, high rate of burning ashes;

Sulfur content is very low, only about 1/20 of the fuel oil, do not take any desulfurization and denitrification measures can meet environmental requirements;

0 "Emissions: Health combustion exhaust substances CO.'s 2 and its absorption during growth CO.'s 2 the same, and instead of fossil energy, reducing the net emissions, in accordance with the" Kyoto Protocol "mechanism, biomass fuel CO.'s 2 ecological" 0 " emission.

4, Straw biomass resources analysis of economic benefits

Wuxi City to the Electrical and Mechanical Co., Ltd. biomass gasifier can be 1 kg of straw fuel into 2 cubic biomass gas = 2400-2600 kcal.

4.1.1 . In the case of natural gas calorific value of 8900 kcal / cubic cubic, the use of special energy TENENG biomass gasifier, 3.4-3.7Kg straw fuel can replace 1 cubic natural gas.

In the straw fuel price of 200 yuan when the replacement of a cubic natural gas need straw fuel costs 0.68-0.74 yuan,

Natural gas prices of 4.5 yuan per cubic, enterprises can save 84-85%.

4.1.2. In straw fuel price of $ 300 when the need to replace a natural cubic straw fuel feed cost 1.03-1.11 yuan,

Natural gas prices for 4.5 yuan per cubic, enterprises can save 75-77%.

4.1.3 . In straw fuel price price of $ 400 when the need to replace a natural cubic straw fuel pricescost 1.37-1.48 yuan,

Natural gas prices for 4.5 yuan per cubic, enterprises can save 67-70%.

Note: Some developed areas to encourage the local government to encourage straw burning, straw processing enterprises to subsidize 200 yuan a ton, so that enterprises can save more.

4.2.1. In the case of diesel fuel calorific value of 10,000 kcal / l, the use of special energy TENENG biomass gasifier, 3.8-4.2Kg straw fuel prices can replace 1 liter of diesel.

In straw fuel price of $ 200 when the need to replace one liter of diesel straw fuel prices cost 0.76-0.84 yuan,

Diesel prices for 7 yuan a liter, businesses can save 84-85%.

4.2.2. When theprice of the straw fuel is 300 yuan, the cost of replacing the 1 liter diesel oil requires the cost of straw fuel price of 1.14 -1.26 yuan,

Diesel prices for 7 yuan a liter , enterprises can save 82-84%.

4.2.3. When the price of straw fuel is 400 yuan , to replace 1 liter of diesel need straw fuel costs 1.52-1.68 yuan,

Diesel prices for 7 yuan a liter , enterprises can save 76-78%.

Note: Some developed areas to encourage the local government to encourage straw burning, straw processing enterprises to subsidize 200 yuan a ton, so that enterprises can save more.

To sum up, if the enterprise is still burning diesel oil to heat, you can use cheap and available biomass raw materials using special biomass gasifier to produce biomass syngas to replace fuel gas equipment.

Another for some gas furnace users and coal-fired boiler users, because some places due to government policy factors, need to burn natural gas users, biomass gasifier and biomass raw materials is also a good choice,

Because if the enterprise to take natural gas pipeline, then the cost is also great, and the current trend of natural gas, natural gas is not enough, so the possibility of price reduction is very small.