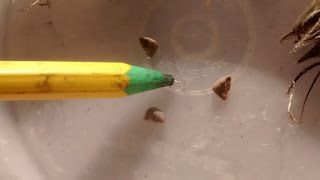

This is the Tap Root of a Kenaf Plant that I pulled

out of the ground 11/21/16. The Kenaf Plant was

dying from the cold temps of St Louis the past few

days. Two days of the temperatures below 33 Deg F

at night is all it took.

These photos were also highlighted at the Hemp

Environmental Forum and the Kenaf Community.

out of the ground 11/21/16. The Kenaf Plant was

dying from the cold temps of St Louis the past few

days. Two days of the temperatures below 33 Deg F

at night is all it took.

Kenaf Plants are also called Indian Hemp by some people.

These photos were also highlighted at the Hemp

Environmental Forum and the Kenaf Community.

|

| Tap Root System of Kenaf Plant from the Kenaf Test Plants |

Additional Kenaf Growing Notes

- The seeds were planted for this plant in midsummer 2016.

- The plants were only hand watered twice due to dry conditions and it wasn't a weren't necessity. I was just playing it on the safe side. After watering them one day it rained that night so I wasted water-aarrgh.

- This particular Kenaf Plant was over 10 feet Tall at harvest time.

- Normal Size Bic Lighter was used for scaling purposes

|

| Kenaf Seeds from Scottys Kenaf Test Plants |

- Remarkable plant that started out as a seed about the same size as a pencil lead.